ON ROAD. ON TRACK.

FROM THE ROAD TO THE TRACK, SEE OUR LINE-UP

Over the years, Avon has proven itself on the road and on race tracks around the world. Discover our full range.

Why Avon?

Up to $50 reward

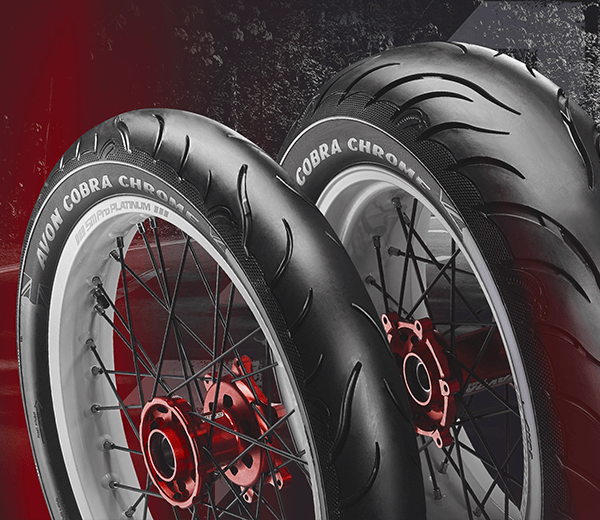

The Avon Cobra Chrome features premium performance, a stylish Cobra themed design and a wide range of sizes.

News